正在焊接第一架执行阿尔忒弥斯任务的猎户座飞船,将宇航员送上月球

At NASA’s Michoud Assembly Facility in New Orleans, technicians from Orion prime contractor Lockheed Martin have welded together three cone-shaped panels on Orion’s crew module for the Artemis III mission that will land the first woman and next man on the Moon.

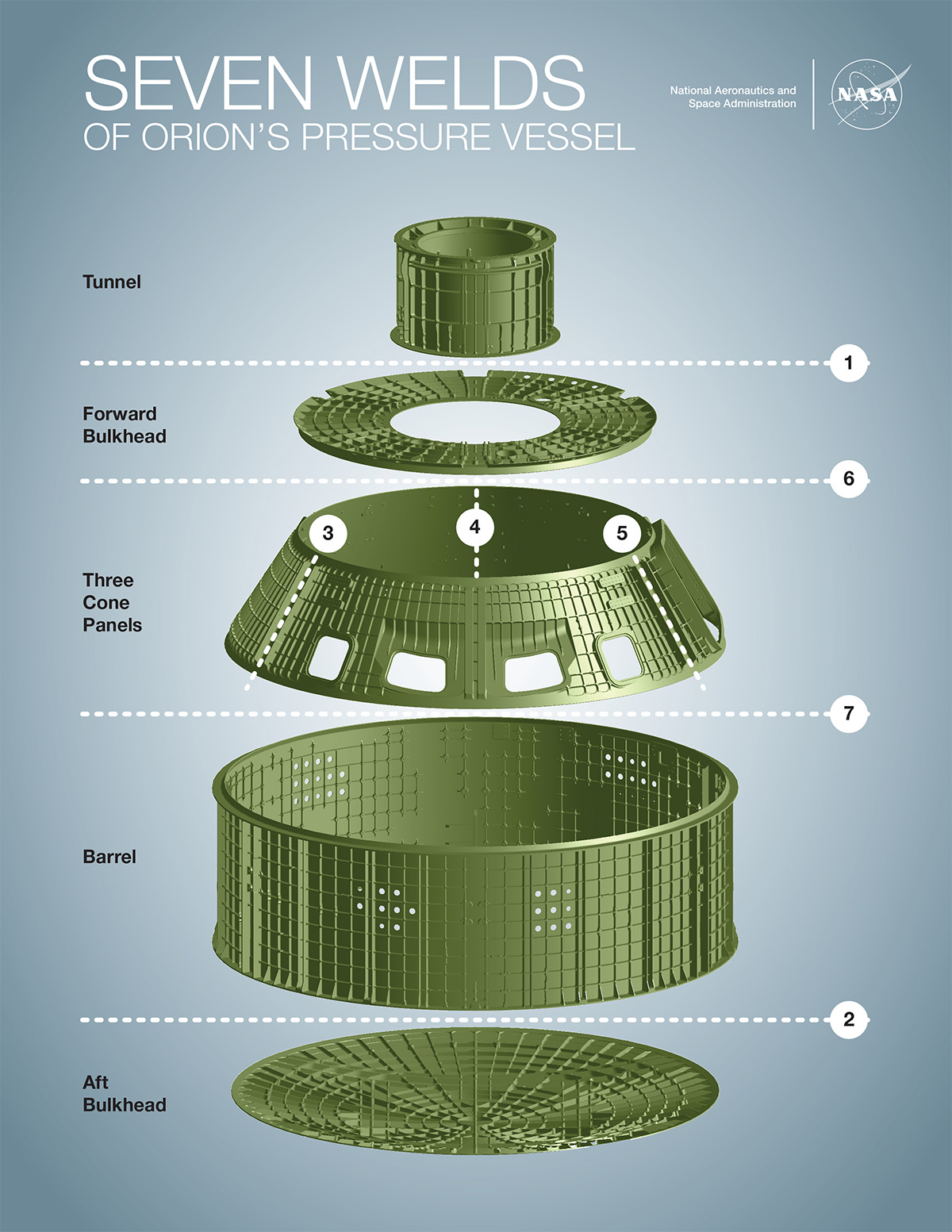

The crew module’s primary structure, the pressure vessel, is comprised of seven machined aluminum alloy pieces that are welded together through a weld process that produces a strong, air-tight habitable space for astronauts during the mission. The pressure vessel is designed to withstand the harsh and demanding environment of deep space, and is the core structure upon which all the other elements of Orion’s crew module are integrated.

With welding complete on the crew module cone panels – one of which contains windows providing astronauts views of the Moon and Earth – work will begin joining the forward bulkhead to the tunnel to create the top of the spacecraft, followed by the barrel and aft bulkhead join to form the bottom of Orion.

Last, the forward bulkhead will be welded to the top of the panels and, for the seventh and closeout weld, the bottom of the cone panels will be joined to the barrel to complete the pressure vessel. Once welding of the Artemis III crew module primary structure is complete, it will be shipped to NASA’s Kennedy Space Center in Florida where it will undergo further assembly beginning this fall.

Orion, the Space Launch System, and Exploration Ground Systems programs are foundational elements of the Artemis program. Artemis I will be the first integrated flight test of Orion and SLS and is targeted to launch later this year. Artemis II will follow and is the first crewed mission, taking humans farther into space than ever before.

Image credit: NASA/Michael DeMocker

在新奥尔良的NASA米胡德组装基地,猎户座主承包商洛克希德·马丁公司的技术人员为猎户座的乘员舱焊接了三个锥形的面板,以执行阿尔忒弥斯3号的登月任务,该任务将使首位女性和下一位男性登上月球。

乘员舱的主要结构是压力容器,由七个经过加工的铝合金部件通过焊接工艺焊接在一起,为宇航员在执行任务期间提供一个坚固的、气密的可居住空间。压力容器的设计是为了承受恶劣和苛刻的深空环境,是猎户座乘员模块的所有其他元素集成的核心结构。

在乘员舱模块上完成焊接后,锥板(其中一个包含可向宇航员提供月球和地球景色的窗户)将开始将前舱壁连接到通道,以形成航天器的顶部,然后是机筒和船尾舱壁连接形成猎户座的底部。

最后,将前舱壁焊接到板的顶部,在第七步和关闭焊缝,将锥形板的底部连接到筒体,以完成压力容器。一旦阿尔忒弥斯3号乘员舱的主要结构焊接完成,它将被运送到佛罗里达州NASA的肯尼迪航天中心,在那里它将在今年秋天开始进行进一步组装。

猎户座、太空发射系统和地面探测系统计划是阿尔忒弥斯计划的基本组成部分。阿尔忒弥斯1号任务将是猎户座和SLS的首次综合飞行测试,计划于今年晚些时候发射。阿尔忒弥斯二号将紧随其后,是首个载人任务,将人类带入比以往任何时候都更远的太空。

影像来源:NASA/Michael DeMocker